|

Taizhou Duoyuan Plastic Mould Co.,Ltd

|

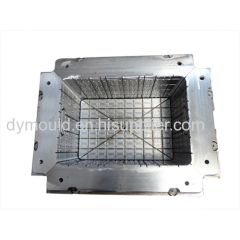

turnover box mould;turn over box;quick production mould;easy transportation turnover box mould; good plastic mould

| Price: | 10000.0 USD |

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

The turnover box mould uses 8 point needle valve type hot feed by using the material of 2738 h from Germany.

Easy for transportation and storage

The turnover box mould uses 8 point needle valve type hot feed by using the material of 2738 h from Germany.

The advantage of one mould with 2 cavities helps Processing efficiency greatly. Efficient cooling can save you lots of time to make production of the turnover box.

If you want to put A turnover box inside B, it's ok, just make the direction of A from left to right, then can put inside easily. This advantage can help transportation and storage, as one turnover box put inside another one only takes little space. If you want to increase the height,it's also ok, put A on top of B by useting the same direction

Model No.: Taizhou Duoyuan Plastic Mould Co.,Ltd..

Production Capacity:600sets/year

Delivery Date:30 days for the first test

Product Material:Steel

Brand Name:DY

Delivery Date:30-60days

Equipments::CNC, Electric Spark Machine..:CNC Machining:0.003to 0.005...

Product:Household appliance

Product:Place of Origin::Zhejiang,China..

Design Software::UG, PROE, Auto CAD, SolidWo..:

MOQ::1 Set

Means of Transport:Ocean,Land,Air

Packing:wooden case

Shaping Mode:Plastic Injection Mould

Product name: Popular air cooler

:Production Capacity:300sets...

..

Means of Transport:Ocean,Land,Air:Packing:wooden case

Injection Mould:High classic very mature:Mould Steel::NAK80,2738,231...

We are professional mould factory,we have already made plastic mould for about 10 years. The pictures you see in our display is the real moulds and products we have made.All of them goes well.

Have you found the shape you are looking for? If yes,please tell me which model you are interested,and we can send you details for the model. If you didnot find what you need, donot worries, please send us your artwork or draft,we can send you more pictures for your selection. Sorry, we cannot put all the pictures in our display.

The following is some necessary information you may need:

Model No.: Taizhou Duoyuan Plastic Mould Co.,Ltd..

Production Capacity:600sets/year

Delivery Date:30-60days

Product Material:Steel

Brand Name:DY

Shaping Mode:::Plastic Injection Mould

features::plastic mould structure

Equipments::CNC, Electric Spark Machine...

CNC Machining:0.003to 0.005mm

Means of Transport:Ocean,Land,Air

Packing:wooden case

Product:Household Product

Shaping Mode:Plastic Injection Mould

Place of Origin::Zhejiang,China(Mainland)

Injection Mould:High classic very mature

.Mould Steel::NAK80,2738,2316,H13,718,S13...

Design Software::UG, PROE, Auto CAD, SolidWo...

MOQ::1 Set

Steel hardness: HRC28-56(according to different steel)

Tooling lead time: 30 days

Mould life: 1, 000, 000 times

Quality assurance: ISO9001Ensures you to us

Steel hardness: HRC28-56(according to different steel)

Tooling lead time: 50 days

Mould life: 1, 000, 000 times

Quality assurance: ISO9001Ensures you to us

Quick Details

· Place of Origin:Zhejiang,China(Mainland)

· Brand Name:DY

· Model Number:DY-1002

· Shaping Mode:Plastic Injection Mould

· Product Material:Plastic

· Product: HOULSEHOULD APPLIANCES

· Condition:New

Packaging & Delivery

Packaging Details: | The packing as your requirement |

Delivery Detail: | 30 days after reciving 50% deposit |

Specifications

1) Surface: MAT finish(textture) Economic Tooling cost

2)Mould life :500,000

3)Thickness:Can be varied if require

Mould Service | with high quality ,long life ,top technic design, prompt delivery, excellent service ,reasonable price |

Technology | adopt CAD/CAM/CAE to design and use advance machines to insure the quality |

Cavity quantity | single or multi cavity |

Cavity /core material | 45#, P20, 718,718H2311, 2738. NAK80,S136,H13 ,2344 Etc according to clients requirement |

Product material | PP, PE, etc |

mould cycle time | 300,000 to1000,000 times |

Machine:

Major equipment | Numbers (set) | Testing Equipment | |||||||||

CNC | 10 | 3D scanner |

| ||||||||

Balancing Machine | 1 | ||||||||||

Wire-cutting | 8 | ||||||||||

Grinding Machine | 2 | ||||||||||

Drilling Machine | 6 | ||||||||||

Business flow

1.Quote | According to sample, drawing and specific requirement. |

↓ | |

2.Discussion | Mold material, cavity number, price, runner, payment, etc. |

↓ | |

3.S/C Signature | Approval for all the items |

↓ | |

4. Advance | Pay 50% by T/T |

↓ | |

5.Product Design Checking | We check the product design. If some position is not perfect, or can not be done on the mould, we will send customer the report. |

↓ | |

6.Mould Design | We make mould design on the basis of confirmed product design, and send to customer for confirmation. |

↓ | |

7.Mold Tooling | We start to make mold after mold design confirmed |

↓ | |

8.Mold Processing | Send report to customer once each week |

↓ | |

10. Mold Modification | According to customer's feedback |

↓ | |

11.Balance settlement | 50% by T/T after the customer approved the trial sample and mould quality. |

Mould process:

6. Mould Maintenance

a) When the mould is vacant, spray the anti-rust oil

b) To clean the gate and cooling system regularly

c) Avoid to use recycled material if the mould is suitable for virgin material only

Our factory is located in Huangyan,Zhejiang province,China. We are near to railway station, bus station and air port,if you have got time, welcome to visit our factory. You will find our workers are professional and kindly, our machines are advance,our boss is very nice to customers,our workshop is well organized.

Multi-source mould comprehensive strength

Dimensions production base with a strong research and development, production team, many professional production lines, the delivery date is guaranteed;

Introduce advanced three dimensional inspection equipment, equipped with perfect quality control system;

Rich experience in injection molding to make our mould to make more reasonable and more efficient, greatly shorten the late production costs.

Any question is welcomed!

With our Best regards!

Taizhou Duoyuan Plastic Mould Co.,Ltd.